LCB30 High current connector

Product Description

| Withstanding Voltage | 600V DC |

| Insulation Resistance | ≥2000MΩ |

| Contact Resistance | ≤1mΩ |

| Flame Level | UL94 V-0 |

| Glowing wire flammability index | GWFI 960℃ |

| Work Temperature | -40~120℃ |

| Housing material | PBT |

| Terminal material | Copper,Silver plated |

| Salt Spray | 48h(Level4) |

| Environmental performance | RoHS2.0 |

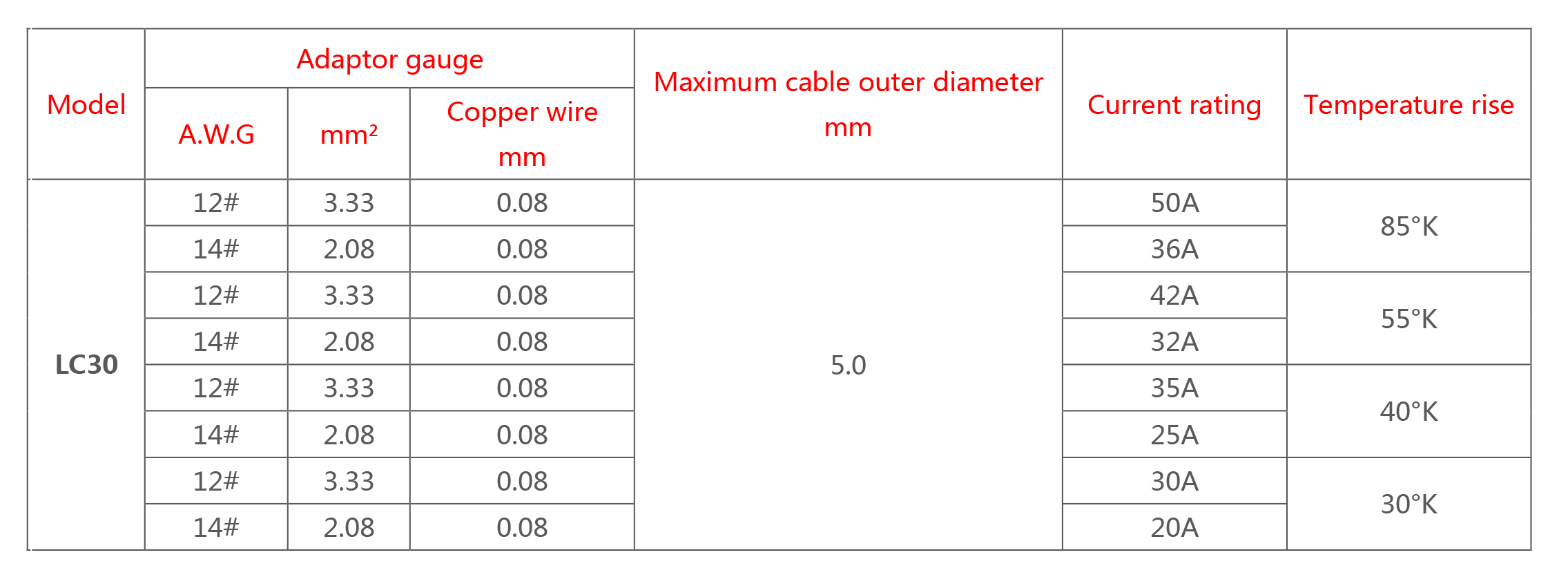

Electric Current

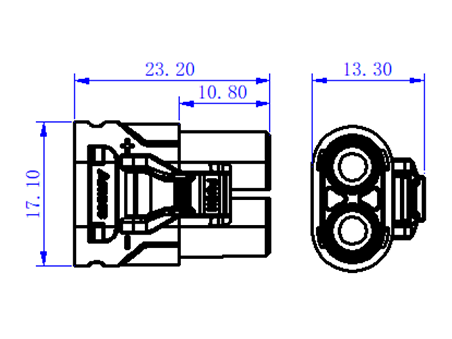

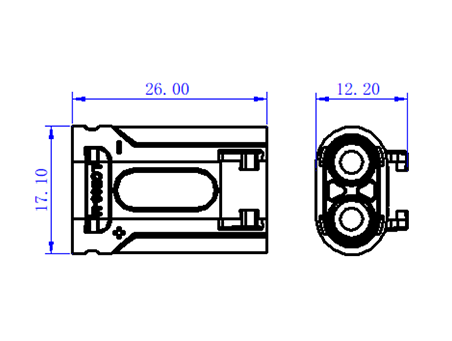

Product Drawings

Product Description

The special connector for intelligent equipment is mainly composed of molded case insulator and conductor contact. The selection of these two materials directly determines the safety performance, practical performance and service life of the connector. Among copper metals, red copper is pure copper, which has better conductivity than brass, white copper or other copper alloys. Therefore, electric power equipment often uses red copper as the conductive material. Amass LC series special connectors for intelligent equipment use red copper contact conductors, which have significant advantages in thermal conductivity, ductility and corrosion resistance. The outer layer of the conductor is silver plated, which greatly improves the current carrying efficiency.

Why Choose Us

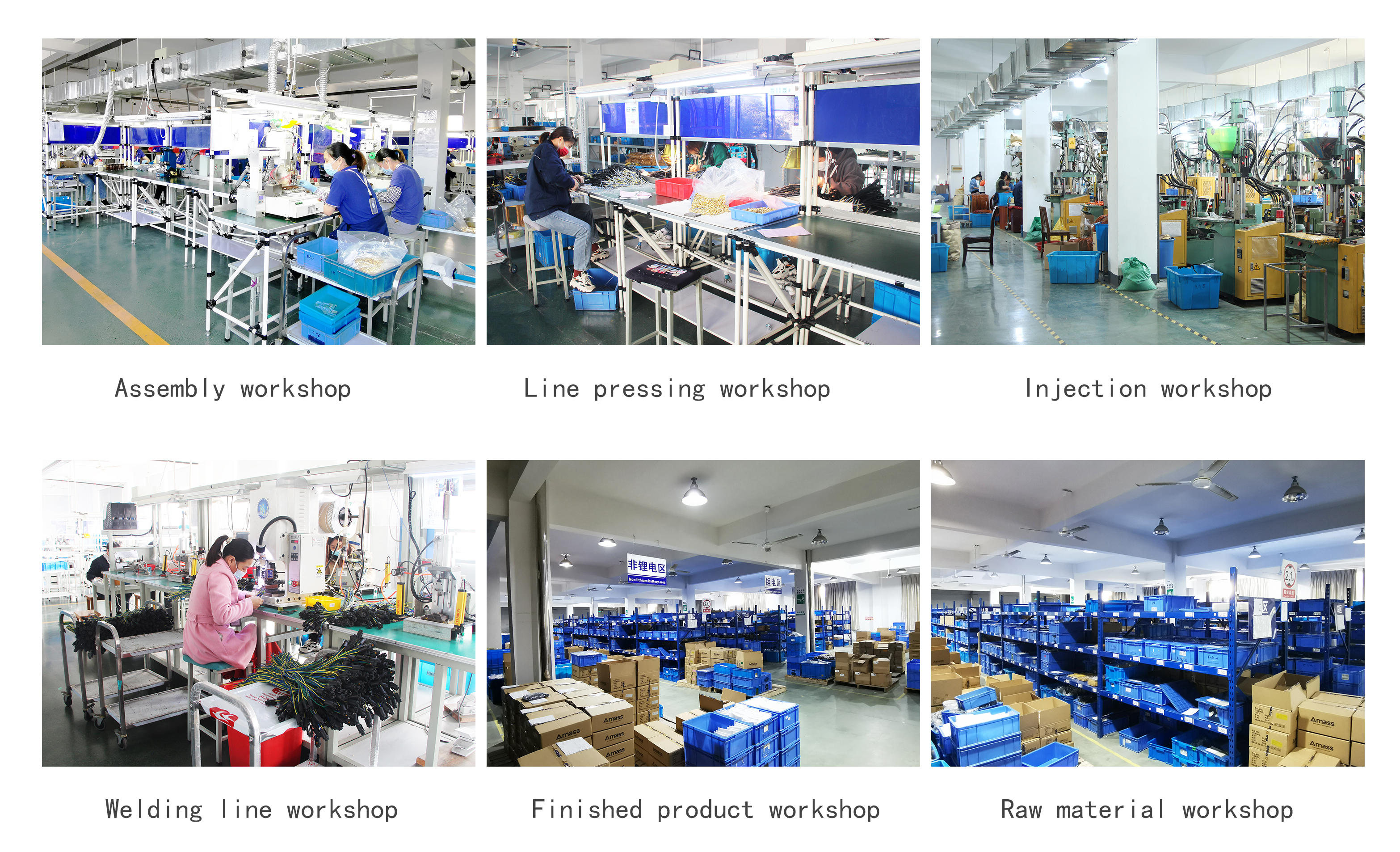

Company strength

The company is located in Lijia Industrial Park, Wujin District, Jiangsu Province, covering an area of 15 mu and a production area of 9000 square meters, The land has independent property rights. So far, our company has about 250 R & D and manufacturing personnel Manufacturing and sales teams.

Honor and qualification

Amass has three national invention patents, more than 200 utility model patents and appearance patents

FAQ

Q: Is your company a trading company or a factory

A: Amass is a provincial high-tech enterprise focusing on the R & D and manufacturing of high current connectors. It was established in 2002 and has 20 years of experience in R & D and production of lithium battery connectors.

Q: How to control connector quality?

A: We have a systematic inspection process for quality control

1. From the product quality control plan, conversion to the inspection standard book, implementation to the quality inspection scheme, the quality control of the process node is formed by the incoming material, product process and final inspection

2. From DVT type test of NPI to ort type test of MP and batch product reliability test, effective product performance guarantee is formed

Q: When will the goods be shipped?

A: This depends on the order quantity and requirements. It takes 3-7 days for conventional products and 25-40 days for customized products. Our daily output is 1 million pcs, so we can deliver goods in a short time.