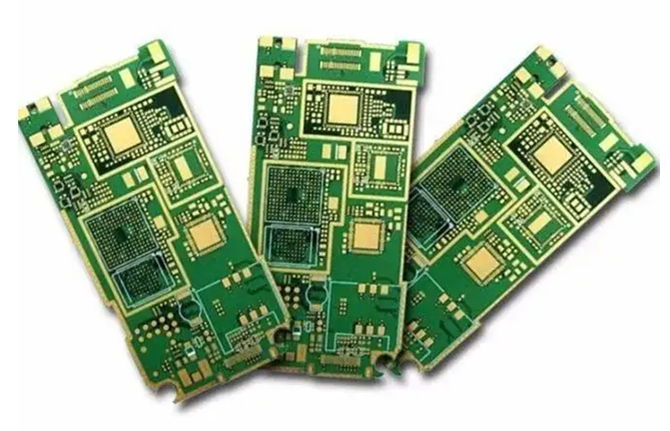

The PCB board (Printedcircuitboard) is the support body of electronic components and the connection provider between electronic components and electrical components. It is almost the infrastructure of all intelligent devices. In addition to the basic functions of fixing various small electronic components, the more important function is to provide the interconnection of the above electronic components.

What are the components of PCB board?

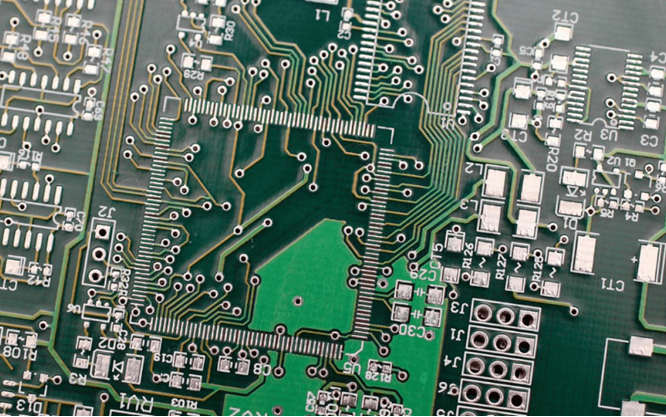

The PCB circuit board is mainly composed of welding pad, through hole, mounting hole, wire, components, connectors, filling, electrical boundary and so on.

(1) Pad: metal hole used for welding pins of components.

(2) Through holes: there are metal through holes and non-metal through holes, wherein the metal through holes are used to connect the pins of components between each layer.

(3) Mounting hole: used to fix the circuit board.

(4) Conductor: electrical network copper film used to connect the pins of components.

(5) Connectors: components used for connecting circuit boards.

(6) Filling: copper application for ground wire network can effectively reduce the impedance.

(7) Electrical boundary: used to determine the size of the circuit board, the board components can not exceed the boundary.

PCB circuit board according to the structure can be divided into PCB single panel, PCB double panel, PCB multilayer board; Common multilayer board is four, six layer board, complex pcb multilayer board can reach more than ten layers.

The more layers of PCB boards, the more stable and reliable the electrical performance, and the higher the cost. The cost difference of single and double panels is not big. If there is no special requirement, all industries will preferentially choose double panels. After all, the performance and stability of the dual panel is better than that of the single panel.

In PCB multilayer board, now the industry is the most used or four, six layer board, consumer electronics industry with higher level pcb board is more. Although multilayer panels have more advantages than dual panels in performance, stability, noise and other aspects, more enterprises and engineers still prefer dual panels for cost considerations.

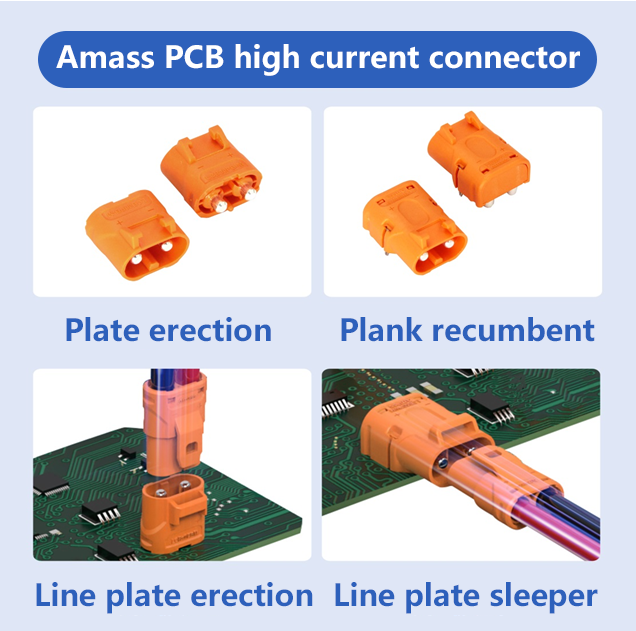

As intelligent devices become more and more complex, more and more accessories are needed, which leads to more and more compact circuits and accessories on PCB. At the same time, the quality requirements of high current PCB board connectors are also improved. Small size PCB board can not only reduce the cost, but also can simplify the design of PCB board, so that the circuit transmission signal loss is smaller.

Amass high-current PCB board connector is only the size of the knuckle, and the contact conductor is silver plated with red copper, which greatly improves the current carrying performance of the connector. Even the small size can have high current carrying, ensuring the smooth running of the circuit, and the diversified installation methods can meet the installation needs of different customers of PCB board.

Amass has different lengths of connectors for PCB circuit boards of different thicknesses, which conforms to the industry standard of exposed panel thickness of 1.0-1.6mm to ensure the normal use of equipment!

Post time: Dec-16-2022