As a senior expert in connectors for PV storage inverters, Amass keeps abreast of the market and customers’ needs, and continuously strengthens product research and development and technological innovation. Continuously improve the level of service, to provide customers with efficient, safe, customized lithium-ion performance connection solutions, in the industry We have been praised in the industry.

The recent heavyweight document “Notice on Encouraging Renewable Energy Power Generation Enterprises to Build or Purchase Peaking Capacity to Increase the Scale of Grid Integration” requires an increase in the scale of installed renewable energy power generation grid integration.

Although there is no direct naming of energy storage, but the market has long regarded energy storage as a directly favorable object.

Due to the variable natural conditions of light and wind, resulting in unstable output power, photovoltaic and wind power can not always meet the power requirements of the grid, that is, abandoned light and wind. This is actually a waste. If this wasted power can be stored, then the cost of renewable energy generation will continue to decrease. And this is also the reason why the capital explosion of energy storage.

After clarifying the general direction, it is more important to look for the segment with the strongest fundamental explosive force.

If we follow this criterion, then inverter is the seed selection hand.

The reasoning behind this is not really difficult to understand. In the PV system, the inverter plays an important function such as AC/DC conversion, power control, and parallel/off-grid switching. And in the inverter, its subsidiary parts inverter connector function quality also need to pay attention to.

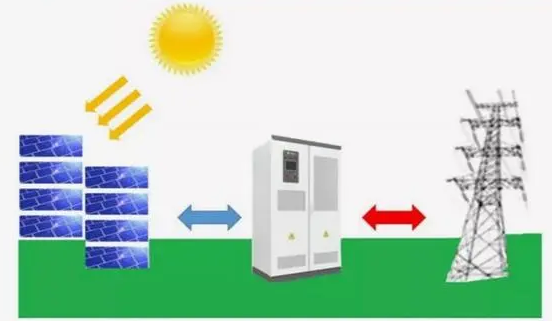

Without the aid of an energy storage system, the electricity generated by the PV is directly connected to the grid through an inverter. With energy storage, the electricity generated by the PV is first stored in the storage system through the inverter, and then the electricity is connected to the grid through the inverter. Although there is one more turn, but it will be able to save the wasted electricity (abandoned light), thus extending the utilization hours of PV.

The growth in demand for inverters is inevitable. According to the forecast of related research, the global PV energy storage inverter corresponding to the installed capacity of up to 104GW in 2025, while the global installed capacity in 2020 was only 5.3GW. that is, 20 times in 5 years, with a compound annual growth rate of more than 80%.

Perhaps some people will say, new energy all segments, the demand is rising, so where is the inverter’s excesses?

Simply put, inverters have consumable logic. The lifespan of a large ground-mounted PV plant is usually around 20 years. The inverter is limited by internal electronic components (IGBT, capacitors, inductors, etc.), the service life is generally no more than 10 years. In other words, a PV power plant

In other words, a PV plant needs at least 2 inverters in its lifetime. This results in inverter demand benefiting not only from incremental PV, but also from stock. A surge in downstream demand usually leads to price increases for upstream products. Only, the biggest point of interest in the inverter industry is not the price increase, but the industry pattern on the supply side. The reason why you don’t have to look forward to price increases, because inverters have both technical barriers, but also to spell low cost. To photovoltaic inverters, for example, 1 inverter connected to a dozen pieces of photovoltaic modules, inverters once the problem, the whole system will be paralyzed. Emphasis on safety, making the early inverters are made in Germany. However, as far as the entire PV industry chain is concerned, inverter is the lowest investment threshold, the most asset-light operation of the link, and this also gives the next low-cost ambush.

Inverter connected to more than a dozen pieces of photovoltaic modules, in which the photovoltaic inverter DC terminals are indispensable, at the same time as the key connecting parts, once the quality of its problems, but also very easy to lead to the paralysis of the entire energy storage system!

Domestic manufacturers later poked through the technical windowpaper, and took out the spirit of big work, quickly spread production capacity (net asset operation of the industry, capacity expansion is rapid), with good quality and low price products, to seize market share at the same time, but also the inverter in the photovoltaic system.Total cost of ownership to less than 10%. Domestic manufacturers sold overseas products, centralized and household inverter unit price of only 0.25 yuan / W and 0.5 yuan / W, far lower than the overseas enterprises 0.57 yuan / W and 0.78 yuan / W selling price.

In addition to the price increase is not favorable to the industry’s own pattern, there will be the risk of falling out with customers. Nowadays, the worst thing in the PV industry chain is the downstream cell and module manufacturers. Upstream who dares to raise prices, they will team up to hammer who a – price increases but was targeted at the silicon, photovoltaic glass is an example. As an expert in cost-effective energy storage connectors, Amass adopts the mechanism of multi-client joint development, which ensures the quality of the products and reduces the cost at the same time, and saves the cost for many customers. The best situation is a win-win situation. Only a win-win situation can ensure sustainable development. In this way, it seems that a good industry pattern is the hen that lays golden eggs in the hands of inverter industry.

Post time: Mar-23-2024