OEM Factory making DC uav power connector

Generally customer-oriented, and it’s our ultimate focus on to become not only essentially the most trustworthy, trustable and honest provider, but also the partner for our clients for OEM Factory making DC uav power connector, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

China DC uav power connector, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The things to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specs for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

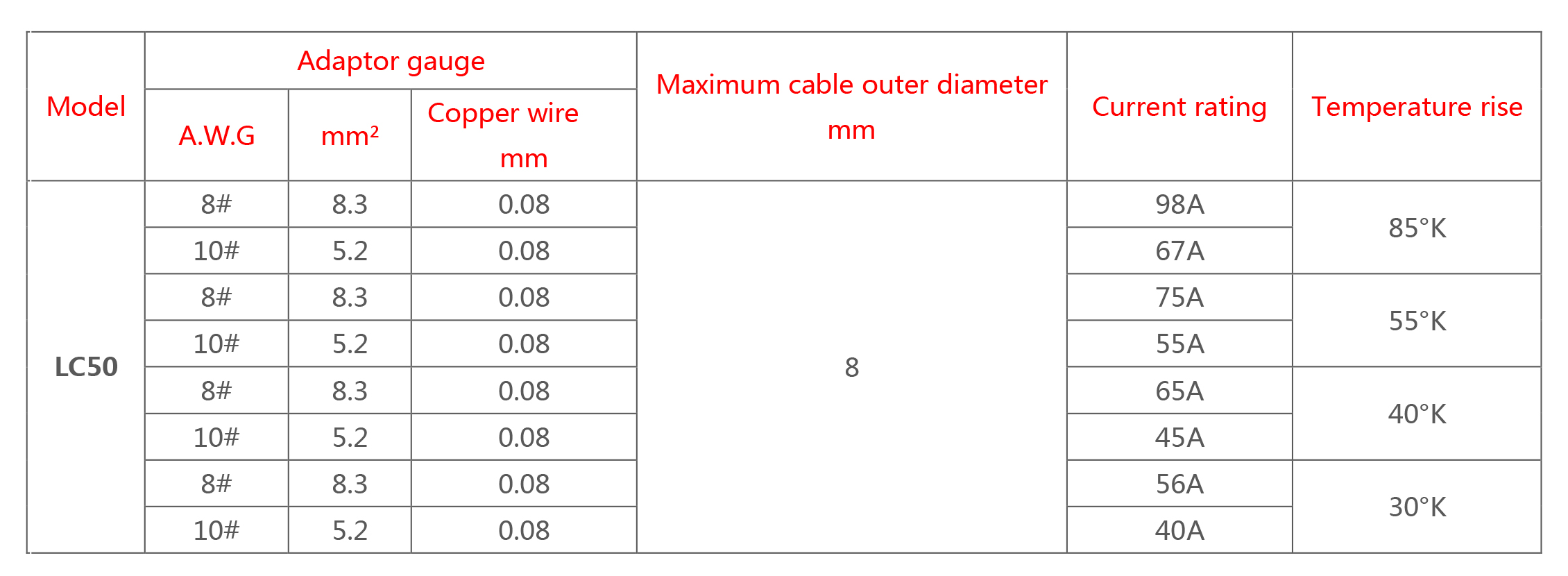

Product Parameters

Electric Current

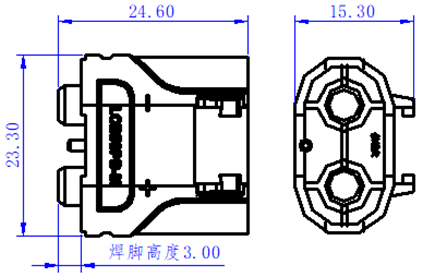

Product Drawings

Product Description

High temperature resistance of connector means that the connector can be used normally in a high temperature environment, and the material also has the required mechanical and physical properties; Amass uses PBT engineering plastics with high, low temperature and high performance that meet the needs of most intelligent devices. The melting point of the PBT insulating plastic shell is 225-235 ℃, which makes the connectors made of materials have high temperature resistance

Amass LC series lithium battery connectors have high adaptability, high reliability and other advantages in the application of solar street lamps. Due to the outdoor service conditions and regional climate, high or low temperature is also a major factor in the test of DC terminals. Extreme high and low temperatures will damage the insulation materials, reduce the insulation resistance and withstand voltage performance, and degrade or even fail the DC terminal performance. LC series DC terminals are made of high temperature resistant material PBT, which can withstand high and low temperature environments from – 20 ℃ to 120 ℃, and can adapt to the long-term continuous and stable operation of street lamps in most temperature environments

Why Choose Us

Quality control system

Quality control system: ISO9001: 2015 quality management system

The quality management system has been introduced since 2009. The quality management system has been running effectively for 13 years

It has been upgraded from version 2008 to version 2015

Equipment strength

Amass has current temperature rise test, welding resistance test, salt spray test, static resistance, insulation voltage

Testing equipment such as plug-in force test and fatigue test, and professional testing capabilities ensure the quality of products

Stability.

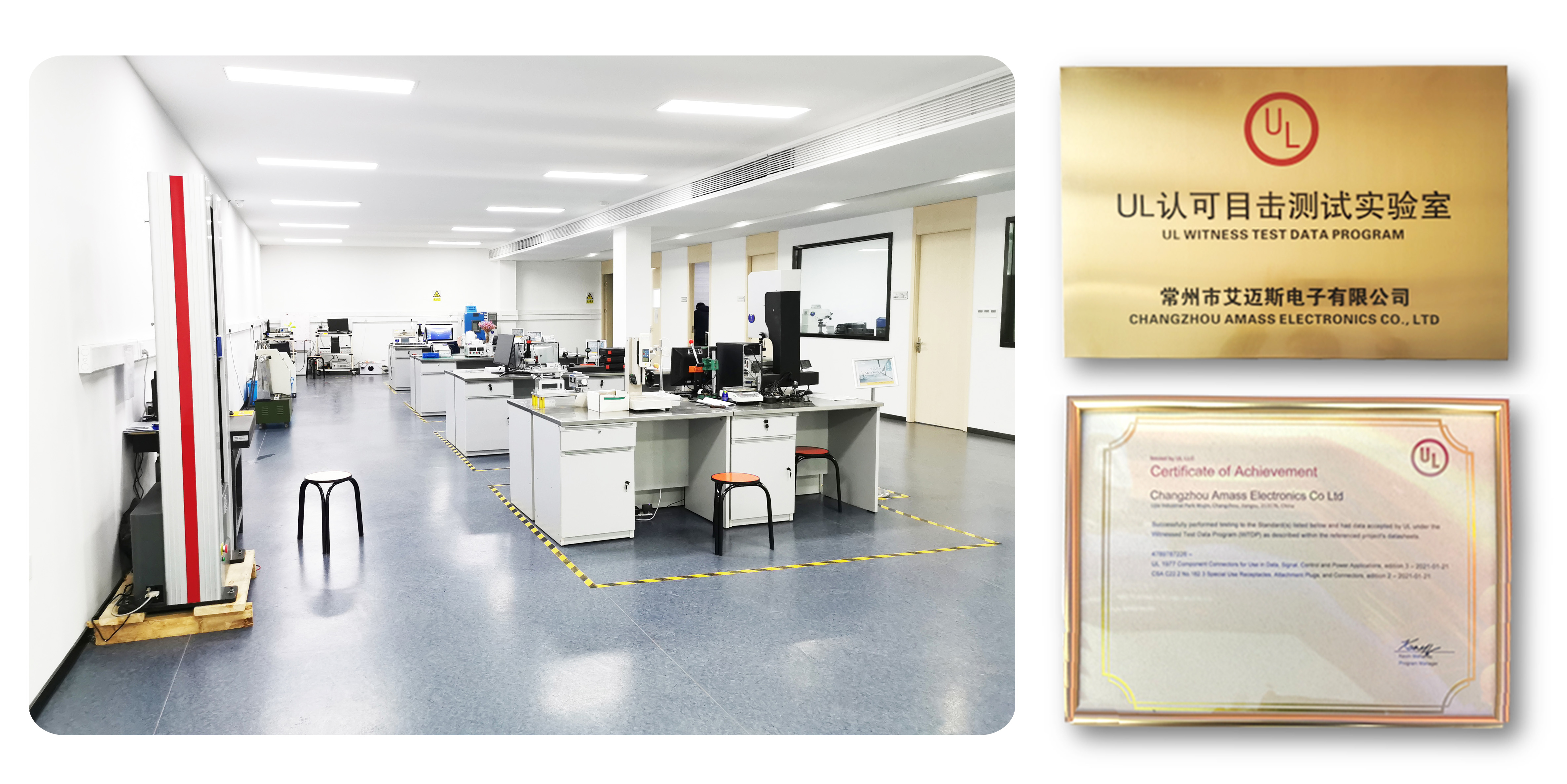

Laboratory strength

The laboratory operates based on the ISO / IEC 17025 standard, establishes four level documents, and continuously improves in the process of operation to continuously improve the laboratory management and technical capacity; And passed UL witness Laboratory Accreditation (WTDP) in January 2021

Applications

Electric Bicycle

Applicable to lithium battery parts of bicycle

Riveting type wiring, no pollution, no welding oxidation and falling off

Electric Vehicle

Control system for electric vehicles controller

Red copper conductor + crown spring design, higher current carrying capacity and longer service life

Energy storage equipment

Applicable to photovoltaic energy storage inverter

It has the characteristics of small volume, large current and low resistance

Intelligent robot

Suitable for intelligent robot motors, controllers and other components

Multiple fool proof design ensures stable and reliable operation of the circuit

Model UAV

Suitable for aerial photography, measurement and other UAVs

Riveting and pressing wiring replaces traditional welding, eliminates oxidation of welding spots, and improves installation efficiency

Small home appliances

Applicable to electric vacuum cleaners

10-300a current coverage to meet the connection needs of lithium batteries with different powers

Tools

Lithium electric hair dryer for garden

Compared with XT Series, groove milling copper parts are upgraded to crown spring copper parts, and their performance and service life are increased year-on-year

Transportation tools

It is suitable for balancing vehicles, balancing wheels and other transportation tools

360 ° crown spring, increased service life, high-strength vibration without instantaneous break

FAQ

Q: When will the goods be shipped?

A: This depends on the order quantity and requirements. It takes 3-7 days for conventional products and 25-40 days for customized products. Our daily output is 1 million pcs, so we can deliver goods in a short time.

Q: Can I customize connector products?

A: Yes, we can customize connector products according to your needs. For specific requirements and contents, please contact our sales personnel.

Q: What patents do your products have?

A: Our company has obtained more than 200 national patent certificates, including patents for inventions, utility models and designsGenerally customer-oriented, and it’s our ultimate focus on to become not only essentially the most trustworthy, trustable and honest provider, but also the partner for our clients for OEM Factory making DC uav power connector, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

China DC uav power connector, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The things to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specs for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.